1. Energy LCD Display Features

LCD displays in energy applications help visualize key metrics like power generation, consumption, and system performance. These displays are commonly used in smart grids, power plants, renewable energy systems, and energy management systems (EMS).

Key Features:

High-Resolution & Clear Data Visualization:

1. HD/4K Resolution: High-definition resolution ensures clear, detailed displays of complex data like power generation, energy consumption trends, or grid status.

2. Graphical Visualization: Displays often present real-time data in charts, graphs, gauges, and meters to make energy-related information more intuitive.

Sunlight Readability:

1. Anti-glare Coating: LCD displays often come with anti-glare and anti-reflective coatings to ensure visibility even in high-brightness conditions, like in outdoor solar farms or field-based energy systems.

2. High Brightness: Displays may have high brightness ratings (e.g., 1000 nits or more) for use in direct sunlight, ensuring clarity in various lighting conditions.

Real-Time Monitoring and Control:

1. Dynamic Updates: Real-time updates to energy metrics, like voltage, current, power factor, and consumption rates, help operators make informed decisions.

2. Control Interfaces: Some LCDs in energy applications serve as part of control panels, allowing operators to adjust settings (e.g., load distribution, grid balancing) from the display.

Energy Efficiency & Low Power Consumption:

1. Energy Saving: LCDs consume significantly less power than older technologies like CRT displays, which is crucial in energy-sensitive environments.

2. Low Power Backlighting: Many energy-efficient LCDs use LED backlighting, which not only saves power but also provides long-term reliability.

Multiple Inputs & Connectivity:

1. Multiple Communication Protocols: LCD displays used in energy systems support various protocols like Modbus, BACnet, and Ethernet/IP to integrate with energy meters, controllers, and sensors.

2. Remote Monitoring: In smart grid and EMS applications, LCD displays enable remote monitoring and control, displaying key energy performance data from centralized locations.

2. Industrial LCD Display Features

In industrial environments, LCD displays are used in machine control, SCADA systems, automation, and process monitoring. These displays need to be robust and capable of handling demanding operational conditions.

Key Features:

Rugged Construction:

1. Vibration & Shock Resistance: Industrial LCD displays must be resistant to vibration and shock (e.g., meeting MIL-STD-810G or similar standards) to ensure reliable operation in harsh factory or field conditions.

2. IP Ratings: Many industrial LCDs have high Ingress Protection (IP) ratings (e.g., IP65, IP67) to make them dustproof and waterproof, allowing them to work in challenging environments like factories, warehouses, or outdoor machinery.

Wide Operating Temperature Range:

1. Extreme Temperature Tolerance: LCDs used in industrial applications are often designed to operate in a wide temperature range, from -40°C to +85°C, ensuring they function reliably in both freezing and high-temperature environments.

2. Thermal Management: Some industrial displays include fanless cooling or heat sinks to prevent overheating in high-performance applications.

High Brightness & Sunlight Readability:

1. Daylight Readable: High brightness LCD displays (often rated at 1000 nits or more) are designed to be visible in direct sunlight or bright indoor environments.

2. Optical Bonding: Optical bonding reduces the gap between layers of the display to enhance visibility in sunlight and improve shock resistance.

Touchscreen Integration:

1. Multi-Touch: Many industrial LCD displays come with multi-touch capabilities for easier interaction, such as zooming in on maps or adjusting system settings.

2. Glove-Compatible: Certain displays are designed to work with gloved hands, making them suitable for environments where workers wear protective gear.

3. Resistive and Capacitive: LCD displays come with either resistive (more durable in harsh conditions) or capacitive (more responsive) touch technologies depending on the application.

Real-Time Process Monitoring:

1. Live Data Visualization: LCD displays show real-time data from industrial machines, such as temperature, pressure, flow rates, and machine health, often in a graphical format like gauges or bar charts.

2. SCADA Integration: Displays can be integrated with Supervisory Control and Data Acquisition (SCADA) systems for real-time monitoring and control of large-scale industrial processes.

3. Alarm and Event Notification: LCDs often have alarm management features, displaying notifications when systems reach critical thresholds or experience failures.

Long Lifespan and Reliability:

1. Durable Backlighting: Many industrial LCDs use LED backlighting, which is more energy-efficient and long-lasting compared to traditional technologies, ensuring longevity and low maintenance costs.

2. Fanless Design: Fanless, passive cooling systems help prevent dust accumulation and failure due to moving parts, making the displays more reliable in industrial environments.

3. Building Management LCD Display Features

In Building Management Systems (BMS), LCD displays are used for controlling and monitoring various building systems such as HVAC, lighting, security, and energy management.

Key Features:

Centralized Control Dashboard:

1. System Monitoring: LCDs provide centralized, easy-to-read interfaces that show the status of key building systems (HVAC, lighting, security) in real time, enabling efficient building operation.

2. Interactive Control: Displays may feature interactive touchscreens that allow building managers to directly control environmental settings (temperature, lighting, etc.).

High Resolution and User-Friendly Interface:

1. Clear Visualization: High-resolution LCD displays present complex building system data in charts, gauges, and text that is easy to interpret for facility managers or operators.

2. Customizable Layouts: Some systems offer customizable dashboard layouts to prioritize data that is most relevant to the operator's role or tasks, such as energy consumption or occupancy patterns.

Energy Monitoring & Efficiency:

1. Energy Consumption Data: BMS LCD displays show real-time energy usage, allowing building operators to track power consumption and make adjustments to reduce costs and increase efficiency.

2. Sustainability Tracking: In more advanced setups, displays may also show data related to a building’s carbon footprint, water usage, or waste management, helping to align with sustainability goals.

Smart Integration:

1. Building Automation: LCDs integrate with building automation systems (BAS) to control heating, ventilation, lighting, and other essential services. These systems can be automated based on occupancy, time of day, or weather conditions.

2. IoT Integration: LCDs may be part of a larger IoT-enabled BMS, allowing for remote monitoring and control via web interfaces or mobile apps.

Alarm & Event Monitoring:

1. Fault Detection: LCDs provide visual notifications and alarms for system failures, security breaches, or HVAC malfunctions, enabling quick responses to issues.

2. Event Logging: BMS displays log important events (e.g., temperature or humidity fluctuations, security alerts) for later analysis or compliance purposes.

Sunlight Readability & High Brightness:

1. Outdoor Usage: In buildings with large windows or outdoor monitoring needs (e.g., parking garages, industrial areas), high-brightness LCD displays (often 1000+ nits) ensure readability in direct sunlight.

2. Anti-Glare Coating: Some BMS LCD displays feature anti-glare coatings or optical bonding to enhance clarity in bright lighting conditions.

Multi-Functionality:

1. Security & Surveillance: Displays often integrate with security cameras or other surveillance systems, allowing operators to monitor and control access points and view live footage.

2. Facility Access: LCDs can display access control information, such as allowing users to unlock doors, track personnel access, or update occupancy schedules.

Summary of LCD Display Features for Energy, Industrial, and Building Systems

Energy LCD Displays:

1. High resolution, real-time energy monitoring, and optimization.

2. Sunlight-readable with high brightness and anti-glare coatings.

3. Low power consumption with LED backlighting for energy efficiency.

Industrial LCD Displays:

1. Rugged, vibration-resistant construction with high IP ratings.

2. Real-time data visualization with SCADA and alarm integration.

3. Multi-touch, glove-compatible interfaces for ease of use.

Building Management LCD Displays:

1. Centralized, user-friendly interfaces for energy and system control.

2. Integration with IoT, HVAC, lighting, and security systems.

3. Sunlight-readable, high-brightness displays for outdoor or high-traffic areas.

Energy,Industrial,Building Display Custom LCD Solutions for Diverse Applications

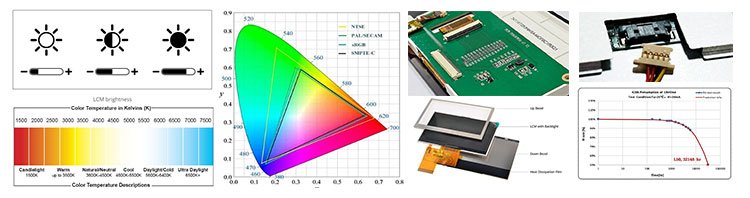

Brightness from 0-3000 for perfect display effect achievement. 100% NTSC makes the vividness of the picture better and the color transition in the picture more natural.

Color Temperature is positive white at around 5500K, warm white (yellowish) at 3500K and also cool white (cold) at 6500K.

Driver circuit with sufficient voltage and current values to meet output requirements and reduce the secondary development cycle.

Heat dissipation for high-brightness products to advance design of reasonable heat dissipation structure.

Power consumption, we increase the brightness without increasing the power consumption.

Cables, Backlighting also requires cables, either through an FPC connected to the LCD's FPC and controlled through a port, or a separate cable that controls it through a connector.LED life reached the standard of 30K hours Min. 50K, 70K, 100K hours are all achievable.

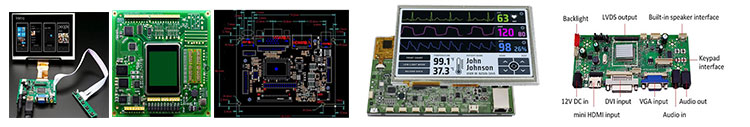

Energy,Industrial,Building Display Touch screen,standard type and customization

Energy,Industrial,Building Display Driver board/adapter board, standard type and design customization

DEMO board, H-DMl board, other customized board, etc.

Energy,Industrial,Building Display Embedded Integrated Solution

UART display solution, H-DMl display solution, Window display solution, Android display solution, Raspberry Pi solution, portable secondary screen solution, etc.