Below are key features commonly found in robot displays:

1. Durability and Ruggedness

· Shock and Vibration Resistance: Robots, particularly those in industrial or outdoor environments, are exposed to vibrations, impacts, and rough handling. Robot displays must be designed to withstand these forces. Some displays are shockproof or vibration-resistant, meeting standards like MIL-STD-810G (military-grade), ensuring they stay operational in demanding conditions.

· Scratch Resistance: The display surface is often designed to resist scratches, especially in robotic environments where they could come into contact with tools, equipment, or abrasive materials.

2. Water and Dust Protection

· IP Rating (Ingress Protection): Robot displays may need to be waterproof or dustproof, depending on the application. For instance, displays with an IP65, IP67, or IP68 rating are protected against dust and water ingress, which is crucial for robots working in wet or dusty environments.

· Sealed Housing: Many robot displays come with sealed enclosures to protect sensitive internal electronics from environmental contaminants.

3. Touchscreen Functionality

· Capacitive or Resistive Touchscreens: Robot displays often include touchscreen interfaces to allow users or robots to interact with the system directly. Capacitive touchscreens offer more sensitive and responsive interactions, while resistive touchscreens can be more suitable in environments where the user wears gloves or when the screen will be exposed to liquids or debris.

· Glove-Friendly Operation: Some robots (especially those in industrial or medical environments) require displays that are responsive to touch even when the operator is wearing gloves.

4. High Resolution and Clarity

· High-Resolution Displays: Robot displays, especially in robotics used for precision tasks, often need high-definition (HD) or 4K resolution to provide detailed visual feedback. This is crucial for robots performing tasks like surgery, inspection, or detailed assembly.

· Wide Viewing Angles: Robot displays typically have wide viewing angles (often 170° or more) to ensure that the screen can be viewed clearly from various positions, especially when multiple people are interacting with the robot.

5. Brightness and Sunlight Readability

· High Brightness: Robots used in outdoor or bright environments (e.g., drones, mobile robots, autonomous vehicles) require displays with high brightness (1000 nits or more) to ensure the screen is visible even in direct sunlight.

· Anti-Glare/Anti-Reflective Coatings: To improve visibility in harsh lighting conditions, robot displays are often treated with anti-glare or anti-reflective coatings, reducing reflections from ambient light or direct sunlight.

6. Wide Temperature Range

· Thermal Resistance: Robots are used in a variety of environments, from freezing cold to high heat. Displays for robots need to function in extreme temperature ranges, typically from -20°C to 70°C (-4°F to 158°F), without losing performance. This is particularly important for industrial, outdoor, or space robotics.

7. Integration with Robotics Control Systems

· Data Display and Feedback: Robot displays often serve as interfaces to display crucial operational data, such as speed, sensor readings, battery levels, or environmental data. They may also provide feedback on the robot’s status, including error messages, warnings, and diagnostic information.

· Real-Time Data Processing: The display should be able to update in real-time, showing dynamic data like video feeds, sensor information, or machine learning outputs as the robot performs its tasks.

8. Customizable User Interface (UI)

· Configurable UI Elements: Robot displays often have customizable interfaces tailored to specific tasks or robot functionalities. Operators or developers can modify the UI to display specific controls, menus, graphs, or maps, depending on the task at hand.

· Multi-Modal Interfaces: Some robot displays can integrate other forms of input, such as voice commands or gesture control, along with touch or button controls for a more flexible interface.

9. Multi-Touch and Gesture Control

· Multi-Touch Capabilities: Robot displays often support multi-touch, enabling users to interact with the robot using more complex gestures like pinch-to-zoom, rotate, and swipe.

· Gesture Recognition: Advanced displays can integrate with sensors or cameras to support gesture-based control, enabling users to interact with the robot’s interface without touching the screen.

10. Low Power Consumption

· Energy-Efficient Displays: As many robots operate on limited battery power, robot displays are often designed to be energy-efficient. Technologies like LED backlighting and OLED displays are often used to minimize energy usage without compromising performance.

· Auto-Dimming: Some robot displays include auto-dimming functionality to adjust the brightness based on ambient light conditions, conserving power when the robot is in darker environments.

11. Communication and Connectivity

· Wireless Communication: Robot displays are often integrated with wireless communication technologies, such as Wi-Fi, Bluetooth, or 5G, enabling remote monitoring or control of the robot via tablets, smartphones, or other devices.

· Ethernet and Serial Ports: For industrial robots or robots in automated systems, displays often support Ethernet or serial communication (RS232/RS485) to interface with other equipment or robots within the system.

12. Flexible Display Options

· Flexible and Curved Displays: Some robots use flexible or curved displays, allowing the screen to follow the contours of the robot's design or to fit into spaces with non-flat surfaces.

· Modular Displays: In some applications, the robot display is modular, meaning it can be swapped out or upgraded easily based on the needs of the task, or it can be part of a multi-display system showing different types of data at once.

13. Safety and Compliance

· Safe Operation in Hazardous Environments: In some industries, robot displays need to comply with safety standards for operation in hazardous areas, such as explosive environments (e.g., ATEX or IECEx certification). These displays are built to ensure that they do not cause sparks or malfunction in dangerous conditions.

· FDA Compliance (for Medical Robots): Displays for medical robots must meet FDA regulations, ensuring they are safe for use in medical environments and comply with standards for human-machine interaction.

14. Audio Integration

· Speaker and Microphone Integration: Some robot displays have built-in speakers and microphones, especially in service robots or humanoid robots, to provide audio feedback, voice recognition, and even communication with humans.

15. Augmented Reality (AR) Integration

· AR Interfaces: Some advanced robot displays incorporate augmented reality (AR) features, providing visual overlays on the display to enhance user interaction with the robot. This could include highlighting areas of interest, showing additional data, or even helping operators with complex tasks.

Applications of Robot Displays

Industrial Robotics:

1. Displaying real-time data such as sensor readings, robotic arm positions, and operational status.

2. Offering a user interface for programming, debugging, and system diagnostics.

Medical Robotics:

1. Assisting with robotic surgery systems by providing real-time video feeds and surgical data.

2. Displaying control panels for medical robots used in rehabilitation or therapy.

Service Robotics:

1. Interfacing with customers or operators in robots used in hospitality, healthcare, or retail, displaying information, directions, and more.

Autonomous Vehicles:

1. Robots designed for autonomous navigation (e.g., self-driving cars, drones) use displays to show navigation data, obstacle detection, and environmental feedback.

Humanoid Robots:

1. Displaying facial expressions, emotions, and interactive touch controls, especially in robots designed for social interaction or entertainment.

Inspection and Surveillance Robots:

1. Showing camera feeds, mapping data, and analysis results for robots used in hazardous environments like oil rigs, nuclear plants, or disaster sites.

Agricultural Robotics:

1. Displaying real-time analytics for agricultural robots, such as crop data, weather, and sensor information for precision farming.

Conclusion

Robot displays are critical interfaces for controlling, monitoring, and interacting with robots across various applications. Whether it's for industrial, medical, service, or entertainment robots, these displays need to be highly durable, energy-efficient, user-friendly, and able to withstand diverse environmental conditions. The integration of features like touchscreens, wireless connectivity, multi-touch capabilities, and rugged construction makes them versatile for any robotic task.

Robot Display Custom LCD Solutions for Diverse Applications

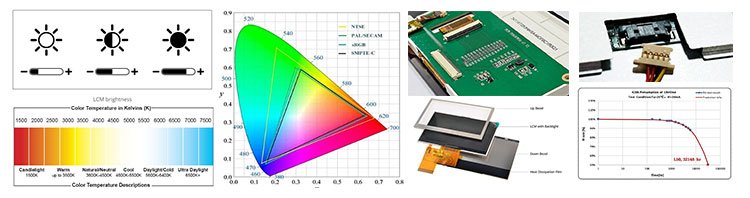

Brightness from 0-3000 for perfect display effect achievement. 100% NTSC makes the vividness of the picture better and the color transition in the picture more natural.

Color Temperature is positive white at around 5500K, warm white (yellowish) at 3500K and also cool white (cold) at 6500K.

Driver circuit with sufficient voltage and current values to meet output requirements and reduce the secondary development cycle.

Heat dissipation for high-brightness products to advance design of reasonable heat dissipation structure.

Power consumption, we increase the brightness without increasing the power consumption.

Cables, Backlighting also requires cables, either through an FPC connected to the LCD's FPC and controlled through a port, or a separate cable that controls it through a connector.LED life reached the standard of 30K hours Min. 50K, 70K, 100K hours are all achievable.

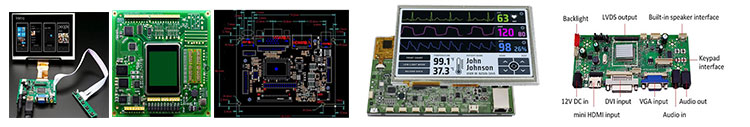

Robot Display Touch screen,standard type and customization

Robot Display Driver board/adapter board, standard type and design customization

DEMO board, H-DMl board, other customized board, etc.

Robot Display Embedded Integrated Solution

UART display solution, H-DMl display solution, Window display solution, Android display solution, Raspberry Pi solution, portable secondary screen solution, etc.