For logistics and portable device displays, key features focus on practicality, durability, and visibility in various working conditions. These devices often need to operate in environments like warehouses, distribution centers, or on-the-go in outdoor or high-mobility settings. Below are the critical features for displays in logistics or portable devices:

1. High Brightness and Readability

- Sunlight Readability: Displays with high brightness (1000+ nits) are essential for outdoor or warehouse environments where glare and direct sunlight can obstruct visibility. This ensures workers can read the screen easily, even in bright conditions.

- Anti-Glare Coating: An anti-glare screen treatment or matte finish reduces reflections and improves screen readability in well-lit areas or outdoors.

- Wide Viewing Angles: A display with wide viewing angles (typically 160° or more) ensures the content is visible to workers from various positions, especially when viewed from different angles or when being used by multiple people.

2. Durability and Impact Resistance

- Shockproof and Drop Resistance: Displays in portable logistics devices should be rugged, designed to withstand drops, vibrations, and rough handling, typically with an IP rating (Ingress Protection) of 65 or higher for dust and water resistance.

- MIL-STD-810G Compliance: Devices built to military standards (e.g., MIL-STD-810G) are tested for environmental durability, including temperature extremes, humidity, and exposure to dust, making them ideal for tough work environments.

- Scratch-Resistant Glass: Hardened, scratch-resistant glass (e.g., Corning Gorilla Glass) ensures the display stays clear and free from damage even with frequent handling.

3. Battery Life

- Extended Battery Life (8-12+ hours): Logistics workers often need devices that last a full shift or more without needing to recharge. A long-lasting battery is essential for fieldwork, warehouse operations, or mobile inventory management.

- Fast Charging: For operations requiring quick turnarounds, devices with fast-charging capabilities ensure minimal downtime.

- Removable Batteries: Some portable devices offer removable batteries for easy swapping, ensuring continuous operation without the need to wait for a recharge.

4. Touchscreen and Interface

- Responsive Touchscreen: A capacitive or resistive touchscreen that works reliably even with gloves on, which is common in cold or high-activity environments.

- Glove-Compatible Touch: Touchscreen sensitivity should be high enough to register inputs even when the operator wears gloves, which is crucial for outdoor or warehouse work where gloves are often required.

- Stylus Input: Some devices might offer stylus support for more precise input, especially useful for signature capture or detailed annotations in logistics tasks.

5. Portability and Form Factor

- Compact and Lightweight: Logistics devices need to be lightweight and compact for easy transport, whether carried by hand, mounted to a vehicle, or used while moving around large facilities.

- Ergonomically Designed: Devices should be easy to hold for extended periods without causing strain, often with rounded edges or handle attachments for better grip and comfort.

- Holster or Mounting Options: Many portable devices come with options for wearing or mounting them (e.g., holsters, vehicle mounts), making it easy to access the device while keeping hands free for other tasks.

6. Connectivity and Wireless Support

- Wi-Fi and Bluetooth: Essential for communication with central servers, inventory systems, or other devices in real-time, ensuring smooth operation for logistics workflows.

- Cellular Connectivity (4G/5G): Devices that can support cellular connections allow for communication and data updates even when there is no local Wi-Fi network available, crucial for field operations or remote sites.

- NFC/RFID Support: NFC or RFID capabilities allow for fast and contactless scanning of tags, which is common in logistics for inventory tracking, asset management, and shipping/receiving operations.

- GPS/Location Tracking: Built-in GPS helps in real-time tracking of portable devices, and can also be useful for vehicle tracking or locating items in large warehouses or outdoor spaces.

7. Customizable Software and Application Support

- Custom UI/Apps for Logistics Tasks: Devices should support customized software that integrates with inventory management, asset tracking, and shipment processing systems, allowing workers to manage tasks such as barcode scanning, order fulfillment, or package tracking efficiently.

- Real-Time Data Syncing: Synchronizing information in real-time with back-end logistics software ensures the most current data is available, reducing errors in order fulfillment and tracking.

8. Data Entry and Barcode Scanning

- Integrated Barcode Scanners: Many portable devices feature built-in barcode scanners (1D or 2D) or even QR code readers, which are essential for inventory management, package tracking, and quick data entry.

- OCR Support: Optical Character Recognition (OCR) capabilities can help scan documents or labels directly, reducing manual data entry time.

9. Multi-Functionality

- Camera Integration: A high-quality camera (often with a flash) allows for photo capture, document scanning, or even video calls for remote assistance during logistics operations.

- Voice Assistants: Some devices integrate voice recognition software, enabling hands-free operation and allowing workers to query information or perform tasks without needing to interact directly with the device.

10. Environmental Adaptability

- Temperature Tolerance: Logistics devices may need to function in various environmental conditions, including hot or cold temperatures. Devices built for temperature extremes (from -20°C to 60°C or higher) are crucial for outdoor work or in refrigerated environments like cold storage warehouses.

- Waterproofing and IP Rating: Devices with a high IP rating (IP67 or higher) are resistant to water and dust, making them suitable for rugged outdoor conditions, rain, or dusty warehouse floors.

11. Security Features

- Data Encryption: For sensitive logistics information, secure communication protocols and encryption ensure that data is protected during transmission and on the device.

- Authentication Options: Multi-factor authentication (e.g., fingerprint scanning, RFID badges) may be integrated to ensure that only authorized users can access the device or system.

- Tamper Detection: Some devices have built-in security features like tamper detection or remote wiping capabilities to protect data in case the device is lost or stolen.

12. Audio and Visual Alerts

- Integrated Speaker or Vibration Alerts: For real-time feedback or notifications (such as task updates or inventory alerts), some portable logistics devices feature sound and vibration alerts.

- LED Indicators: Some devices may include visual indicators (like LED lights) for quick status checks or operational notifications.

13. Flexible Input/Output Ports

- USB, HDMI, or Other I/O Ports: For easy data transfer or peripheral connection (like printers, scanners, or charging docks), these devices often include multiple I/O ports.

- Docking Stations: Many portable logistics devices are designed to fit into docking stations for recharging and data synchronization when not in use.

14. Cost-Effectiveness

- Affordable Yet Rugged: While many logistics devices need to be robust, they also need to be cost-effective, especially in environments that require a large number of devices (such as warehouses, retail locations, and shipping facilities).

- Scalable Solutions: Devices should be scalable for large deployments, allowing businesses to easily manage and upgrade as the logistics needs grow.

15. Long-Term Support and Warranty

- Extended Warranty and Support Services: A warranty that covers defects, accidental damage, and wear-and-tear is important, especially for portable devices that endure frequent handling in high-activity logistics environments.

- Software Updates: Regular software and firmware updates ensure devices stay up-to-date with the latest functionality and security patches.

These features make logistics and portable devices highly versatile for a variety of applications, from real-time inventory management and order fulfillment to field-based inspections and package tracking. If you're looking into a specific device type or use case within logistics, Eurotech can provide more focused recommendations!

Logistics/Portable Device Display Custom LCD Solutions for Diverse Applications

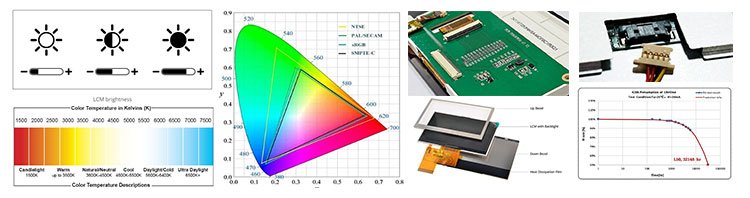

Brightness from 0-3000 for perfect display effect achievement. 100% NTSC makes the vividness of the picture better and the color transition in the picture more natural.

Color Temperature is positive white at around 5500K, warm white (yellowish) at 3500K and also cool white (cold) at 6500K.

Driver circuit with sufficient voltage and current values to meet output requirements and reduce the secondary development cycle.

Heat dissipation for high-brightness products to advance design of reasonable heat dissipation structure.

Power consumption, we increase the brightness without increasing the power consumption.

Cables, Backlighting also requires cables, either through an FPC connected to the LCD's FPC and controlled through a port, or a separate cable that controls it through a connector.LED life reached the standard of 30K hours Min. 50K, 70K, 100K hours are all achievable.

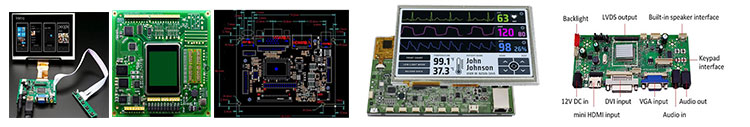

Logistics/Portable Device Display Touch screen,standard type and customization

Logistics/Portable Device Display Driver board/adapter board, standard type and design customization

DEMO board, H-DMl board, other customized board, etc.

Logistics/Portable Device Display Embedded Integrated Solution

UART display solution, H-DMl display solution, Window display solution, Android display solution, Raspberry Pi solution, portable secondary screen solution, etc.