They need to meet the unique requirements of the rail environment, which often includes challenging weather conditions, constant vibrations, and a need for easy visibility in various lighting conditions.

Key Features of Rail Industry Displays

1. High Durability and Ruggedness

· Shock and Vibration Resistance: Rail environments, especially inside trains, are subject to constant vibrations and occasional shocks. Displays used in the rail industry need to be shockproof and vibration-resistant, often meeting military standards like MIL-STD-810G or IEC 60068.

· Scratch-Resistant Screens: Display surfaces are often designed to resist scratches and impacts, especially in public-facing applications like station displays or driver control panels.

2. Weather and Environmental Protection

· IP Rating (Ingress Protection): Rail industry displays need to be able to withstand various environmental conditions such as rain, dust, extreme temperatures, and exposure to sunlight. IP65, IP67, or even IP68 rated displays provide protection against dust and water ingress.

· Temperature Resistance: These displays are built to function in a wide temperature range, from -20°C to 70°C (-4°F to 158°F), to ensure reliable performance in extreme weather conditions, including heat, cold, and humidity.

3. High Brightness and Sunlight Readability

· Outdoor Visibility: Displays used in stations or on trains (such as information boards or signage) must be highly bright (typically 1000 nits or higher) to ensure readability in direct sunlight. This is especially important for systems used in train stations, platforms, or on exterior train panels.

· Anti-Glare Coating: Displays often feature anti-glare or anti-reflective coatings to improve readability in various lighting conditions, reducing reflections from bright sunlight or artificial lights.

4. Wide Viewing Angle

· Wide Viewing Angles: For displays used in stations or passenger cabins, wide viewing angles (often up to 170°) are essential to ensure the content is legible from different positions within the train or station.

· Optimized for Public Spaces: Displays must be legible and clear for large groups of people, ensuring passengers can read the information regardless of where they are positioned in the train or station.

5. High-Resolution and Clarity

· HD or 4K Resolution: For signage, ticketing displays, and control panels, high-resolution displays (typically HD or 4K) are often used to ensure that text, images, and videos are clear and legible. High resolution reduces pixelation, especially when displaying real-time schedules, maps, or security footage.

· Clear Text and Icons: In applications such as ticketing systems or driver control interfaces, clear legibility is crucial for fast reading, even at a distance or in motion.

6. Touchscreen and Interactive Features

· Capacitive Touchscreens: Touch-enabled displays are often used for ticketing machines, interactive kiosks, or even in-cabin control panels. Capacitive touchscreens offer more responsive and durable interaction, with multi-touch capabilities.

· Resistive Touchscreens: In situations where users may need to interact with the display while wearing gloves (e.g., train conductors), resistive touchscreens are often preferred, as they can be used with gloved hands or stylus pens.

· Multi-Touch Support: Some interactive displays in stations or on trains may support multi-touch gestures, allowing users to zoom, scroll, or select options efficiently.

7. Real-Time Data Display

· Dynamic Schedule and Information Display: In both stations and onboard trains, displays often show real-time updates such as train schedules, delays, and important announcements. This requires high-speed data refresh capabilities to ensure the information is always up-to-date.

· Emergency and Safety Information: Rail industry displays may be used for showing safety instructions, emergency alerts, and other critical information to passengers. This includes train status updates, emergency evacuation procedures, and safety messages.

8. Low Power Consumption

· Energy Efficiency: Displays in the rail industry are often designed to be power-efficient to help minimize the energy consumption of onboard systems or station-based equipment. Technologies like LED backlighting and OLED are often used to reduce power consumption.

· Auto Dimming: Displays in trains or stations may have auto-dimming features that adjust the brightness based on ambient light conditions, optimizing energy usage and reducing glare.

9. Safety and Compliance

· Fire and Safety Standards: Displays used in trains and stations must comply with fire safety standards, often featuring flame-retardant housings and materials.

· EMC (Electromagnetic Compatibility): Rail industry displays must meet EMC standards to prevent interference with train communications and signaling systems, ensuring reliable operation.

· Non-Intrusive and Non-Disruptive: The design of the display should not distract or interfere with passengers or train operators. For instance, driver-facing displays should be designed to minimize distractions while providing the necessary information.

10. Flexible and Modular Designs

· Modular Displays: Some rail displays are modular, meaning they can be customized for different applications (e.g., large public-facing signage, smaller train control panels, etc.). These systems can be adjusted in size, shape, and functionality as needed.

· Customizable Layouts: Displays in the rail industry often feature customizable layouts, where users can adjust content such as train schedules, advertisements, news, or emergency messages.

11. Network Connectivity

· Wi-Fi and Ethernet: Displays in trains or stations often need network connectivity to receive real-time data or update content remotely. Wi-Fi or Ethernet connectivity is used to pull the latest information from centralized systems.

· Remote Monitoring and Control: In some cases, displays can be monitored and controlled remotely, allowing station managers or train operators to make adjustments or updates in real-time without needing to physically access the devices.

12. Integration with Other Systems

· Signaling and Monitoring Systems: Displays are often integrated with signaling systems and train control panels. For example, onboard displays show vital train status information such as speed, direction, and operational data.

· Passenger Information Systems: Displays in stations or trains are part of broader passenger information systems (PIS), which synchronize content across multiple screens, provide messaging, and integrate with train operations.

13. Anti-Fog and Anti-Condensation Features

· Fog-Resistant Displays: Displays in trains or stations often include anti-fog coatings to prevent condensation, especially in environments with fluctuating temperatures or high humidity levels (e.g., on trains in rainy weather or near the ocean).

14. Multiple Content Display

· Mixed Media Support: Rail displays often support a variety of content types, from static text and images to dynamic video feeds and animations. This allows stations to display multiple forms of information, such as entertainment, advertisements, and real-time train schedules.

· Dual Mode Display: Some displays in the rail industry are designed for dual-mode use, such as advertisements and public announcements, allowing the same screen to switch between different types of content.

Applications of Rail Industry Displays

Passenger Information Displays (PIDs):

o Used on platforms and inside trains to provide real-time train schedules, announcements, delays, and other important information for passengers.

o LED or LCD screens are commonly used for these displays due to their high visibility and ease of maintenance.

Train Control Panels:

o Displays used by train operators or conductors to monitor train systems, display critical operational data (speed, fuel, location, etc.), and manage train performance.

o These often have touchscreen or button-controlled interfaces for interacting with various control functions.

Onboard Entertainment and Information Systems:

o In luxury trains or high-speed trains, onboard entertainment systems utilize high-resolution displays for offering movies, games, or news channels to passengers.

o Interactive screens may allow passengers to control their entertainment choices or access additional train information.

Station Signage and Advertisements:

o Digital signage in train stations displays real-time schedules, news, and advertisements, often using large-format LED displays or LCD screens.

o These displays are designed to be highly visible and durable, capable of operating continuously in public environments.

Ticketing Machines and Kiosks:

o Interactive kiosks with touchscreen displays allow passengers to buy tickets, check schedules, and get other travel-related information.

Safety and Emergency Displays:

o In case of an emergency, certain rail displays show evacuation routes, safety instructions, and alerts about potential hazards. These displays must be highly visible and easy to read, even in stressful situations.

Signal and Control Systems:

o Rail signaling systems, including train station signals and trackside displays, provide real-time train positioning, train arrival/departure times, and other critical operational data.

Conclusion

Rail industry displays are designed with durability, visibility, and functionality in mind, supporting everything from passenger information and station signage to complex train control and safety systems. With the ability to withstand environmental challenges, operate in diverse lighting conditions, and display real-time data, these displays are essential for smooth and safe rail operations.

Rail Industry Display Custom LCD Solutions for Diverse Applications

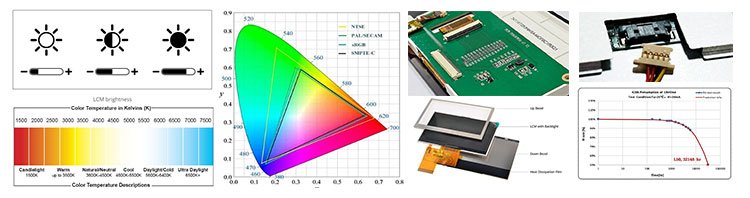

Brightness from 0-3000 for perfect display effect achievement. 100% NTSC makes the vividness of the picture better and the color transition in the picture more natural.

Color Temperature is positive white at around 5500K, warm white (yellowish) at 3500K and also cool white (cold) at 6500K.

Driver circuit with sufficient voltage and current values to meet output requirements and reduce the secondary development cycle.

Heat dissipation for high-brightness products to advance design of reasonable heat dissipation structure.

Power consumption, we increase the brightness without increasing the power consumption.

Cables, Backlighting also requires cables, either through an FPC connected to the LCD's FPC and controlled through a port, or a separate cable that controls it through a connector.LED life reached the standard of 30K hours Min. 50K, 70K, 100K hours are all achievable.

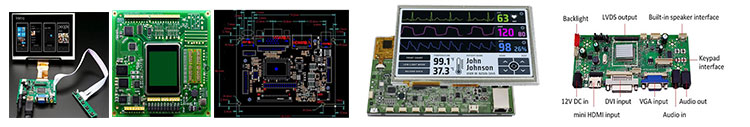

Rail Industry Display Touch screen,standard type and customization

Rail Industry Display Driver board/adapter board, standard type and design customization

DEMO board, H-DMl board, other customized board, etc.

Rail Industry Display Embedded Integrated Solution

UART display solution, H-DMl display solution, Window display solution, Android display solution, Raspberry Pi solution, portable secondary screen solution, etc.