Aerospace Display Features are crucial for the safety, functionality, and efficiency of systems in aircraft, spacecraft, and other aerospace applications. These displays need to meet stringent requirements, including high performance, durability, readability in various lighting conditions, and integration with complex avionics systems. Aerospace displays are used in cockpit instruments, flight control systems, navigation systems, communication interfaces, and more.

1. High Brightness and Contrast

· Brightness: Aerospace displays need to be highly visible under a wide range of lighting conditions, from bright sunlight to low-light or night environments. High brightness (typically between 500 to 1500 nits or more) is essential to ensure that displays remain legible in direct sunlight or during flight in clear skies.

· High Contrast: Displays should provide high contrast ratios (e.g., 1000:1 or higher) to improve readability in challenging lighting conditions. This is crucial for ensuring that vital flight information, such as navigation, altitude, and speed, is clear and easy to read.

2. Multi-Layer Anti-Glare Coating

· Anti-Glare: Displays should feature anti-glare coatings to prevent sunlight reflections from obscuring the screen, ensuring that pilots can read information clearly even in bright conditions.

· Anti-Reflective Coating: In addition to reducing glare, anti-reflective coatings help reduce reflections that could distract the pilot, improving the overall usability of the display.

3. Wide Viewing Angles

· Aerospace displays should offer wide viewing angles (e.g., 170° or more horizontally and vertically) so that information can be easily read by multiple users or from different angles in the cockpit. This is especially important in multi-crew aircraft or for displays viewed by both pilots.

4. Rugged and Durable Construction

· Shock and Vibration Resistance: Aerospace displays are exposed to significant vibration and shock during flight, so they need to be built with rugged enclosures and materials to handle these forces. Typically, displays are tested for vibration resistance in accordance with standards such as MIL-STD-810 or RTCA DO-160.

· Temperature Resistance: Aerospace systems operate in extreme temperatures, both high and low. The display must function reliably across a wide temperature range, typically from -40°C to +70°C or even broader in some cases.

· Impact Resistance: The display should be impact-resistant to prevent damage from rough handling, turbulence, or accidental impacts. This can be achieved with hardened glass like Gorilla Glass or other specialized materials.

5. Touchscreen and Gesture Support

· Touchscreen Capability: In modern aerospace displays, touchscreen functionality is increasingly common for ease of interaction, enabling pilots or crew to interact directly with the system. However, this needs to be glove-compatible and resistant to the harsh environment (e.g., sweat, dirt, and moisture).

· Gestural Control: Some advanced aerospace systems support gesture-based controls, where pilots can control certain functions by swiping or tapping the screen, which helps in improving operational efficiency.

6. High Resolution and Color Accuracy

· Resolution: High-resolution displays are critical for displaying detailed data such as maps, radar images, and flight plans. Many aerospace displays have Full HD (1920x1080) resolution, but in more advanced systems, higher resolutions (e.g., 4K) may be used for high-end avionics displays that require greater detail.

· Color Accuracy: Accurate color reproduction is vital in distinguishing between different data types (e.g., green for safe, red for warnings, blue for water, etc.) and for clear visualization of radar, satellite imagery, or other critical data.

7. Integrated Flight Management Systems (FMS)

· FMS Integration: Aerospace displays are often integrated with Flight Management Systems (FMS) to provide real-time information on navigation, altitude, speed, and heading. These systems need to communicate seamlessly with the display to ensure accurate data is presented to the pilot.

· Waypoints and Route Display: The display needs to clearly show flight plans, waypoints, airways, and routing information, allowing for quick and easy visual references during flight operations.

8. Multi-Function Display (MFD) Capability

· Aerospace displays often serve as multi-function displays (MFDs), meaning they can display various types of data and information, such as:

o Navigation maps

o Weather radar

o Engine status

o System diagnostics

o Tactical display for military applications

· MFDs need to have seamless switching between different data types and an intuitive user interface for easy operation during flight.

9. Data Integration and Communication

· Integration with Sensors and Systems: Aerospace displays are connected to a wide range of sensors and systems, including weather radar, GPS, altimeter, pitot tube (for airspeed), and more. The display needs to show real-time data from these systems in a cohesive and understandable format.

· Communication: The display system may also be integrated with communication systems, allowing pilots to send or receive information through digital communications or radio.

10. Head-Up Display (HUD) Integration

· HUD Integration: In some modern aircraft, the aerospace display is integrated with the Head-Up Display (HUD), which allows pilots to view critical flight information without needing to look down at traditional cockpit instruments. The HUD projects vital flight data (e.g., speed, altitude, navigation) onto a transparent screen directly in the pilot's line of sight.

11. Redundant Systems and Fault Tolerance

· Redundancy: In aerospace applications, redundant display systems are critical for ensuring safety. If one display fails, a secondary display should take over without disruption to flight operations. This is especially important in cockpit avionics.

· Built-In Self-Test (BIST): Aerospace displays often come with a built-in self-test feature that ensures the display is operational and alerts the crew if a failure is detected, ensuring system reliability.

12. Long Lifecycle and Maintenance

· Longevity: Aerospace displays are designed for long operational lifecycles, often lasting several decades in service. They are built with high-quality components to reduce the need for maintenance and replacement.

· Ease of Maintenance: Aerospace displays are typically designed with modular components that can be easily serviced or replaced in the field, minimizing downtime and operational disruption.

13. Energy Efficiency

· Low Power Consumption: While aerospace displays need to be bright and high-performing, they also need to be energy-efficient to ensure minimal impact on the aircraft's overall power consumption. This is particularly crucial for battery-powered or electrical systems in aircraft.

· Power-saving Modes: Many aerospace displays include power-saving modes that can adjust brightness or switch to lower power states during less critical phases of the flight (e.g., cruising).

14. Flexible Form Factor

· Customizable Sizes and Shapes: Aerospace displays come in various sizes, from small instrument panels to large glass cockpits that take up significant portions of the cockpit. Customization is key for different aircraft types (e.g., commercial jets, military aircraft, unmanned aerial vehicles).

· Curved Displays: Some aerospace applications use curved displays to enhance the pilot’s field of view and reduce distortion at the edges of large screens.

Applications of Aerospace Displays:

Cockpit Displays:

Displays show critical flight information such as altitude, airspeed, navigation, heading, and attitude, often integrated into a glass cockpit. These systems are highly customizable and display a combination of Primary Flight Displays (PFDs), Navigation Displays (NDs), and Engine Indication and Crew Alerting Systems (EICAS).

Head-Up Displays (HUDs):

These are used to project essential flight data (altitude, speed, heading, navigation) directly in the pilot’s line of sight. This enables pilots to keep their focus on the outside environment while receiving critical information.

Military Aircraft Displays:

In military aviation, displays often show tactical data, including radar, threat detection, weapon targeting, and communication systems. These displays are designed to meet military standards for ruggedness and performance.

Unmanned Aerial Vehicles (UAVs):

UAV displays integrate real-time telemetry, camera feeds, and system diagnostics, allowing operators to monitor and control unmanned aircraft remotely.

Satellite and Spacecraft Displays:

Spacecraft displays need to manage communications, navigation, and system status over long distances, often using low-resolution, high-reliability displays to ensure clarity in extreme conditions (e.g., high radiation environments or microgravity).

Aerospace Display Custom LCD Solutions for Diverse Applications

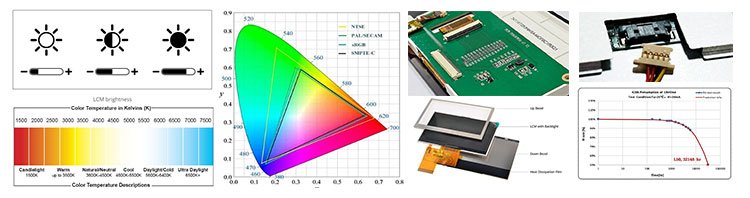

Brightness from 0-3000 for perfect display effect achievement. 100% NTSC makes the vividness of the picture better and the color transition in the picture more natural.

Color Temperature is positive white at around 5500K, warm white (yellowish) at 3500K and also cool white (cold) at 6500K.

Driver circuit with sufficient voltage and current values to meet output requirements and reduce the secondary development cycle.

Heat dissipation for high-brightness products to advance design of reasonable heat dissipation structure.

Power consumption, we increase the brightness without increasing the power consumption.

Cables, Backlighting also requires cables, either through an FPC connected to the LCD's FPC and controlled through a port, or a separate cable that controls it through a connector.

LED life reached the standard of 30K hours Min. 50K, 70K, 100K hours are all achievable.  Aerospace Display Touch screen,standard type and customization

Aerospace Display Touch screen,standard type and customization

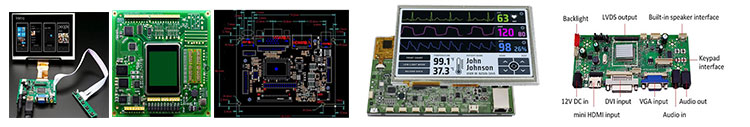

Aerospace Display Driver board/adapter board, standard type and design customization

DEMO board, H-DMl board, other customized board, etc.